Home>Products>Fried Wheat Flour Snacks Making Machine>Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line

Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line

- Fried Wheat Flour Snacks Making Machine

Fried Wheat Flour Snacks Making Machine

- China

- ISO9001,CE

- One set Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line

- [email protected]

- 12*1.6*2.3m

- contact with us

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 37

Microwave dryer dehydration sterilization machineChina

-

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Fried Wheat Flour Snacks/Salad making machine

Product Description

Introduction (application)

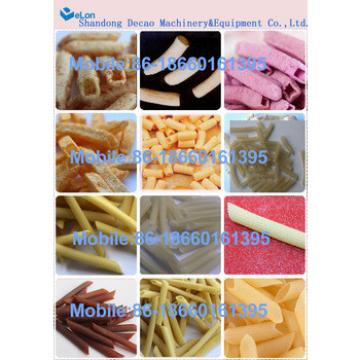

Fried wheat flour snacks, salad, bugles and rice crust process line uses wheat flour,rice flour, and corn flours as the raw material to produce flour food by screw extrusion technique. By using different moulds, the food will have different shapes, such as rice crust,pillow, pizza roll, shell, whelk, cat-ear, pea, triangle etc. The shapes of product are similar to the real one and they taste crispy and delicious after fried and flavored. No need a dryer, simple process, less investment. It is the best choice for middle-sized companies.

Technological Process

Technological Process

Raw Material Configurations→ Mixing→ Conveyance→ Extrusion→ Shaping→ Frying→ Flavoring

Equipment Configurations

1.Flour Mixer: Stir mixed raw materials evenly with a certain amount of water. Choose different GY flour mixer model according to different output requirements.

2.Spiral Conveyor: Convey stirred raw materials into feeding hopper of extruder.

3.Extruder: Select different GY extruder model based on clients’ raw materials and output capacity requirement. With the help of special control cabinet, extruder is able to extrude the raw material under different temperature & pressure, and produce puffed products. The shapes of products can be changed by changing the modules in extruder.

4.Shaping Machine: Use GY traction & cut-off machine or 3D pellets shaping machine or Bugles shaping machine or multi-functional shaping machine to shaping the products according to different products shapes.

5.Frying Machine: Choose GY different automatic fryer model or continuous fryer model according to different producing requirements to frying snacks to be crispy and a better taste.

6.Flavoring Line: Select square flavoring machine, single-roller flavoring line or dual-roller flavoring line, based on output and product properties. Single-roller and dual-roller flavoring line combine the functions of flavoring with seasoning and oil injection together.

Characteristics

§Various models to meet different output capacity requirements.

§Flexible configurations to meet different produce, budget and workshop layout requirement.

§Vast raw material range to produce different final products by only one production line.

§Different shapes and appearances of final products can be made by changing different modules in extruder.

§High automation and accurate control system to save labor cost and improve the quality of final products.

§Independent temperature control system is able to realize zone temperature control, electronic induction, accurate & visual digital display.

§Feeding system without material returning. It is unnecessary to clean barrel and screw in case of restarting or material replacement.

§Screw adopts high-performance nitride alloy steel with strong wear-resistance and Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line service life.

§Food-grade stainless steel. Neatness and easy clean.

Technical Parameters

Model | Output Capacity | Supply Voltage |

GY8/65-2 | 100 ~ 150 Kg/h | 380V/50Hz Three phases or 220V/60Hz Single phase |

GY8/65-4 | 150 ~ 220 Kg/h | |

GY8/70-1 | 150 ~ 260 Kg/h | |

GY8/75-1 | 200 ~ 400 Kg/h |

Workers:

Normally 1-2 operators are sufficient for production.

Samples:

fully automatic Cheetos machine

Packaging & Shipping

Packing:

Strong Fumigation-Free Wooden Case or 20'GP or 40'HQ

Delivery:

Within 30 working days for standard products. Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line delivery time is needed for special customized products.

Shipping:

Sea transportation, land transportation or air transportation according to different conditions.

Our Services

1. Manufacture:

1) Keep the quality the first.

2) Make more products benefit to customers' need.

________________________________________________________________________

2. Online/Sale service:

1) Supper and solid quality.

2) Fast and punctual delivery

3) Standard export package or as customers' need.

________________________________________________________________________

3. Pre-sale Service:

1). Related machine technical parameter will be supplied.

2). According to customer’s factory size, factory layout can be provided.

3). According to customer’s material cost, general formulation can be prepared.

4). Special machine can be supplied according to customer’s request.

5). Professional advice about market, machines, processing, materials, packing can be supplied

6). Suggesting professional ship agent or helping book ship as customer request.

________________________________________________________________________

4. After-sale service:

1)Allocation chart as the buyer’s request will be supplied.

2) Reasonable equipment place scheme is available according to client plant’s size.

3)Provide all basic formulas; various types are optional.

4) Operation manual will be supplied after shipment.

5) One year warranty, lifetime maintenance.

6) Free quick-wear parts will be sent.

7) Local installation service is available (free restricted to Chinese market).

8)Free training.

________________________________________________________________________

5. Other cooperate service:

1) Technology knowledge share.

2) Factory building advising.

3) Business expansion advising.

Company Information

Company Introduction:

Jinan Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line Machinery & Equipment Co., Ltd.(GY Machinery)is the professional manufacturer for advanced and high efficient extrusion food machinery.

GY has an expert team with around 15 years experiences in this extrusion machine industry. We constantly research extrusion technology and explore food process in order to benefit our clients producing better and creative food.

After years of research, GY has more than twenty production lines with different functions and capacities to meet different customer requirements:

1.Direct Puff Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line Process Line

2.Breakfast Cereal & Corn Flakes Process Line

3.Core-Filling Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line Process Line

4.Pellet Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line Process Line

5.3D Pellet Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line Process Line

Pani Puri/ Golgappa Puri/ Golgappa fryum/ fryum

6.Cheetos/Kurkure/ (Nik) Naks/Corn Curls Process Line

7.Triangle Chips/ Doritos/Tortilla Chips Process Line

8.Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line

9.Pasta Process Line

10.Nutritional / Artificial Rice Process Line

11.Nutritional Powder/Baby Food Process Line

Modified Starch Process Line

12.Bread Crumb Process Line

13.TVP/TSP/Soya Protein Process Line

14.Pet Food Process Line

15.Mini Burger Patty/Nuggets/Fillet/Steak Process Line

16.Mini Instant Noodle Process Line

17.Mini Biscuit Process Line

FAQ

Q1.Are you a manufacturer or a trading company ?

A:We are a professional manufacturer of food making machine line.

Q2.Where is your factory located ? How can I visit there ?

A:Our factory is located in Jinan City, Shandong Province, about 2.5 hour train from Beijing.

Q3.What’s the price of your food making machine line?

A:Please contact us from the right side by Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line, we will reply you as soon as possible.

Q4.How to support me if i don't know how to use it?

A:Free training within the warranty by tel and mail or skype. We also can dispatch our

technician to customer’s company to provide training and support if customer agree

the air ticket and hotel.

Q5.What's the pre-sale service of your company?

A:Related machines’s technical parameter will be supplied to customer.

1. According to customer’s factory size, factory layout can be provided in advance.

2. According to customer’s material cost, general formulation can be prepared well.

3. Special machine can be supplied as customer’s request.

4. Professional Advice about Market, machines, processing , materials, packing can be supplied.

5. Suggesting professional ship agent or helping book ship as customer request.

Q6. What's the after-sale service of your company?

A:

1. Allocation chart as the buyer’s request will be supplied.

2. Operation manual will be supplied after shipment.

3. One year warrantee, life time maintenance with cost price.

4. Free easy broken spare parts will be sent with container .

5. First installation can be done by engineer.

6. Training workers in customer’s factory.

Q7. If machines wearing parts need changing, what should we do?

A:We can offer the wearing parts all the time, and offer video.

Q8. What's the payment terms if we want to buy the machines?

A:L/C, 100%T/T,T/T 30% down payment, 70% balance before delivery.

Contact Us

- Microwave dryer dehydration sterilization machine

- AddressBawang Road, Licheng District, Jinan City, Shandong Province

- Phone(Working Time)86-531-4897119

Related News

| Microwave Technology in Traditional Chinese Medicine Production |

Product Categories

- laboratory drying equipment

- chinese herb dehydration and sterilization

- chinese medicine herb drying equipment

- chemical powder drying equipment

- Microwave dryer and sterilization machine

- chinese medicine extraction machine

- paper dehydrator and sterilizer

- paperboard drying equipment

- microwave fast food heating machine

- latex products drying machine

- microwave oven tunnel machine

- Microwave roasting equipment

- microwave sterilizer equipment

- Oil seeds Processing Line

- soybean oil machine

- Sesame Oil machine

- coconut oil processing machine

- mustard oil machinery

- Shea Nut Oil machine

- Castor Oil machine

- Walnut Oil machine

- Corn Germ Oil machine

- Rapeseed Oil machine

- Rice Bran Oil machine

- microwave dryer equipment

- cottonseed oil machine

- Sunflower Oil machine

- Peanut Groundnut Oil machine

- Small Scale Oil Refining Line

- palm fruit machine

- solvent extraction machine

- Full Continuous Refining Line

- Biodiesel Machine

- flaxseed oil Machine

- camellia oil Machine

- moringa seed oil machine

- Complete oil production line

- Seed Hydraulic Press Machine

- Large Scale oil Machine

- Edible Oil Filling Line

- oil Pretreatment Equipment

- Oil Extraction Equipment

- puffed snack food machinery

- corn filling snack machinery

- Fish food machine

- Animal food machinery

- Fried Kurkure machine

- Fried cheetos machine

- Baked kurkure machine

- Baked cheetos machine

- Corn flakes Machinery

- Frying snacks machinery

- Nacho Chips machinery

- Corn Chips machinery

- Tortilla machine

- doritos machine

- bugles machine

- Soyabean protein machine

- Extrusion food machine

- Macaroni pasta machinery

- Nutritious artifical rice food machine

- Bread crumbs machine

- Nutritional powder machine

- Modified starch machine

- modify starch machine

- Potato Chip Machine

- rice cracker machine

- Biscuit Production Line

- Textured Soya Protein machine

- Instant Noodles Production Line

- Fried Wheat Flour Snacks Making Machine

- Nutrition Bar Making Machine

- snack Food Packing Machines

fried snack food making mahine

fried snack food making mahine ss304 stainless steel extrusion snacks process line food processing industries

ss304 stainless steel extrusion snacks process line food processing industries fried wheat flour chips processing line

fried wheat flour chips processing line puff corn snacks making line

puff corn snacks making line extruder bugle snack processing line

extruder bugle snack processing line