Home>Products>Biscuit Production Line>2015 Hot Sale Wafer Production Line 27-75 Plates

2015 Hot Sale Wafer Production Line 27-75 Plates

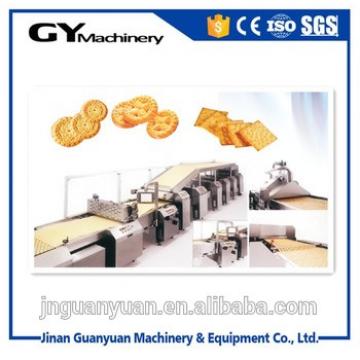

- Biscuit Production Line

Biscuit Production Line

- China

- CE,ISO9001:2000

- One set 2015 Hot Sale Wafer Production Line 27-75 Plates

- [email protected]

- (6000-16000)*1700*2260mm

- contact with us

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 192

Microwave dryer dehydration sterilization machineChina

-

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

KHG-27 to 75 plates/moulds Gas Heated Wafer production Line

The wafer production lines are Kehua Foodstuff Machinery Manufacturer's main products. The baking oven has 27 to 75 baking plates for the customers to choose according to the required capacity.

Features:

a. Full automatic controlled, easier operation and save the labor costs(only need 5 workers to operate the machines).

b. According to HACCP design, with high production effeciency, stable and reliable operation and long service life.

c. Special energy conservation design, reduce energy consumption.

d. The motors, bearings, PLC and other components adopt international and chinese famous brand.

e. All parts contacting with the food are made from SUS304 Stainless steel and food-grade materials.

f. Making high quality wafer biscuits,the percent of pass (clear design, plump wafer, baked evenly) after the broken wafer collecting machine is up to 98%.

g. Have CE, ISO9001:2000, FM certifications.

h. Provide the best service and perfect after sale service.

Equipment:

The standard configuration of this wafer production line: 1.Batter mixer 2.Baking oven 3.Wafer sheet connecting machine 4.Wafer sheet cooler 5.Wafer sheet collecting machine 6.Cream spreading machine 7.Clooing tower 8.Cold blower/Refrigeration system 9.Wafer book conveyor 10.Wafer cutting machine 11.Cream mixer 12.Smashing machine

Production Process:

batter mixing ---- wafer baking ---- cooling ---- cream spreading ---- book cooling ---- cutting

1.Batter mixer

a. Dimension: 1720×1100×1000mm.

b. Power: 4.5Kw, the mixing motor power is 3Kw, and the pump power is 0.75Kw×2.

c. It can mix the 25kg flour with water and other materials to be 65kg batter within 3minutes.

2.Gas baking oven

a. Gas heating, baking time: 2-3 minutes, standard baking plates size: 470X325mm, the maximum size: 500X350mm, standard pattern size: 2.5X2.5X0.5mm, baking plate surface can be plated with hard chrome.

b. Standard wafer sheet dimension: 464×321×(2.5-3.2)mm, weight of wafer sheet: 50-60g.

c. Gas components: Italy and Japan brand.

d. Motor: SEW of German brand.

e. Pneumatic components: FESTO or SMC.

f. Running wheel bearing: SKF VA201.

g. Pressing roller bearing: SKF Explorer.

h. AC contactor and air switch: Schneider of France brand.

i. Programming unit: 2015 Hot Sale Wafer Production Line 27-75 Plates S7-200 of German brand or MISTUBISHI FX-1N of Japan brand.

j. Iinverter: Panasonic of Japan brand or Danfoss of Denmark brand.

k. Touching screen: 2015 Hot Sale Wafer Production Line 27-75 Plates Smark line 1000 or Hakko of Japan brand.

l. Photocell: cylinder-shaped Sick of German brand.

m. Proximity switch: SD-105 Optex of Japan brand.

3.Wafer sheet connecting machine

a.Dimension: 2300×700×850mm.

b.Power: 0.37Kw.

4. Wafer sheet Cooler

a.Dimension: 1300×700×2300mm.

b.Power: 0.18Kw.

c.Effective cooler holder quantity: 42pcs.

5.Wafer sheet collecting machine

a.Dimension: 2000X700X760mm.

b.Power: 0.18Kw,380v/3Phase/50Hz(SEW).

6. Cream spreading machine

a.Dimension: 3000×1200×1300mm.

b.Total power: 4.12Kw, motor power: 2.62Kw,380V/50Hz; heating power: 1.5Kw,220V/50Hz.

7. Cooling tower

a.Dimension: 3130X1200X3660mm, with 4 layers.

b.Power: 1.11Kw, main motor power: 0.75Kw, conveyor motor power: 0.18KwX2.

c.Effective wafer book holders: 112books.

d.The input cold air temperature: 5 ℃, and the relative humidity is 55%.

8. Cold blower/Refrigeration system

a.Dimension: 2200X1100X1800mm.

b.There are two 5HP compressors.

c.The power of the centrifugal fan is 1.5Kw/380V/50Hz.

d.The temperature range is 0~5℃.

e.The temperature controlling precision: ±1℃.

f.There is one set of evaporator.

g.There is one set of condenser.

9. Cutting conveyor

a.Dimension: 1500×700×(780-1100)mm, weight: 80Kg.

b.Power: 0.18Kw.

10. Cutting machine

a.Dimension: 1620×2300×1240mm,weight: 400kg.

b.Power: 0.75Kw.

c.The maximum cutting speed is 9books/min.

d.The blade point is 0.3mm.

11. Cream mixer

a.Dimension: 1840×850×1350mm,weight: 1000kg.

b.Power: 5.05Kw, mixing motor power: 4.5Kw, turnover motor power: 0.55Kw.

c.The two mixing speeds are 1400r/min and 700r/min.

12. Smashing mahine

a.This equipment is used to grind the discarded wafer in to a reusable form.

b.Power:3Kw.

Remark:

Space: machines using 60 square meter

Packaging: iron and waterproof membrane

Container: one 40’HQ

Warranty: one year

[Note]: We can make different pattern for the plate according to client’s demands.

If you would like the baking oven heated by electricity, please click here:

http://kehuachina.en.2015 Hot Sale Wafer Production Line 27-75 Plates.com/product/60049193135-50118489/full_automatic_wafer_biscuit_baking_machine_production_line_with_27_to_63_baking_plates.html

Contact Us

- Microwave dryer dehydration sterilization machine

- AddressBawang Road, Licheng District, Jinan City, Shandong Province

- Phone(Working Time)86-531-4897119

Related News

| Microwave Technology in Traditional Chinese Medicine Production |

Product Categories

- laboratory drying equipment

- chinese herb dehydration and sterilization

- chinese medicine herb drying equipment

- chemical powder drying equipment

- Microwave dryer and sterilization machine

- chinese medicine extraction machine

- paper dehydrator and sterilizer

- paperboard drying equipment

- microwave fast food heating machine

- latex products drying machine

- microwave oven tunnel machine

- Microwave roasting equipment

- microwave sterilizer equipment

- Oil seeds Processing Line

- soybean oil machine

- Sesame Oil machine

- coconut oil processing machine

- mustard oil machinery

- Shea Nut Oil machine

- Castor Oil machine

- Walnut Oil machine

- Corn Germ Oil machine

- Rapeseed Oil machine

- Rice Bran Oil machine

- microwave dryer equipment

- cottonseed oil machine

- Sunflower Oil machine

- Peanut Groundnut Oil machine

- Small Scale Oil Refining Line

- palm fruit machine

- solvent extraction machine

- Full Continuous Refining Line

- Biodiesel Machine

- flaxseed oil Machine

- camellia oil Machine

- moringa seed oil machine

- Complete oil production line

- Seed Hydraulic Press Machine

- Large Scale oil Machine

- Edible Oil Filling Line

- oil Pretreatment Equipment

- Oil Extraction Equipment

- puffed snack food machinery

- corn filling snack machinery

- Fish food machine

- Animal food machinery

- Fried Kurkure machine

- Fried cheetos machine

- Baked kurkure machine

- Baked cheetos machine

- Corn flakes Machinery

- Frying snacks machinery

- Nacho Chips machinery

- Corn Chips machinery

- Tortilla machine

- doritos machine

- bugles machine

- Soyabean protein machine

- Extrusion food machine

- Macaroni pasta machinery

- Nutritious artifical rice food machine

- Bread crumbs machine

- Nutritional powder machine

- Modified starch machine

- modify starch machine

- Potato Chip Machine

- rice cracker machine

- Biscuit Production Line

- Textured Soya Protein machine

- Instant Noodles Production Line

- Fried Wheat Flour Snacks Making Machine

- Nutrition Bar Making Machine

- snack Food Packing Machines

New Products

HYZDGD-800 Produce Different Shapes Cookies Biscuit Production Line Industrial Cookie Machine Price Cookies Production Line

HYZDGD-800 Produce Different Shapes Cookies Biscuit Production Line Industrial Cookie Machine Price Cookies Production Line western-style pastry making machine/wafer biscuit production line/walnut cake baker

western-style pastry making machine/wafer biscuit production line/walnut cake baker Full automatic biscuit production line made in Shanghai HG-SWB1000

Full automatic biscuit production line made in Shanghai HG-SWB1000 commercial walnut cake machine cake forming machine

commercial walnut cake machine cake forming machine HG500 new design small scale biscuit production line

HG500 new design small scale biscuit production line