Home>Products>Nacho Chips machinery>Cost-effective doritos corn chips nacho bugles production line

Cost-effective doritos corn chips nacho bugles production line

- Nacho Chips machinery

Nacho Chips machinery

- China

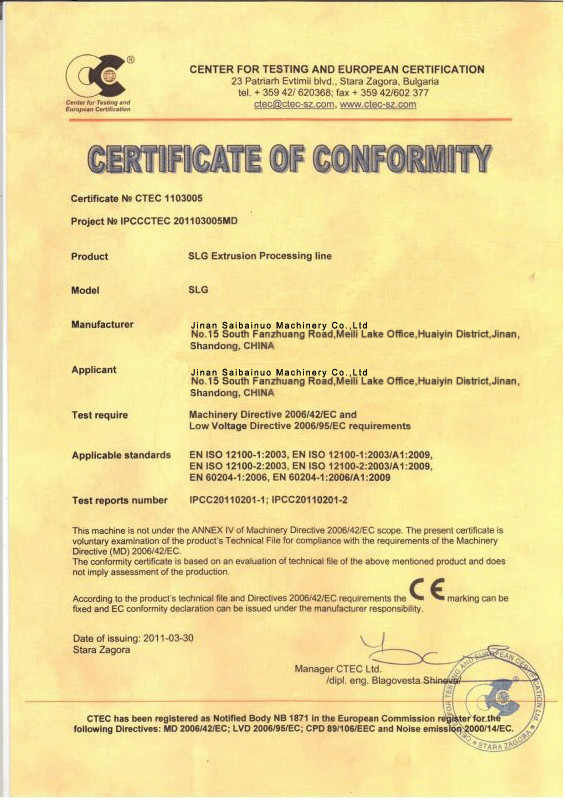

- CE ISO

- One set Cost-effective doritos corn chips nacho bugles production line

- [email protected]

- 20000mm*1300mm*2300mm

- contact with us

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 116

Microwave dryer dehydration sterilization machineChina

-

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

1.The brief description of cost-effective doritos corn chips nacho bugles production line:

| Mode | SLG65 | SLG70 |

| Capacity | 120-150KG/H | 220-250KG/H |

| Power | 70KW | 100KW |

| Dimension | 18000×2000×2500mm | 20000×2000×2500mm |

2.The brief introduction of cost-effective doritos corn chips nacho bugles production line:

corn chips nacho bugles frying snacks are made from corn powder, which are cut and then fried.The main raw materials are corn powder, vegetable oil, salt and water. Although usually made of yellow corn(as pictured), they can also be made of white, or red corn. After frying and flavoring, we get very crunchy triangle or other shapes chips which are popular with both children and adult.

3. Raw Materials: corn flour, wheat flour and other grains as rawmaterials

4. Products: All shapes of Doritos, shapes like round, triangle, hexagon etc. The size of products can be changed according to clients’ requirements.

5. Capacity: 120-150 KG/H, 220-250 KG/H

6.Flow chart: Flour Mixer---Screw Conveyer----screw Extruder---Roller Cutting Machine---Hoister---Separate Drum---Vibrate Feeder---Continuous Fryer---Vibrate De-oil Machine---Flavoring

7. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries8. Machines Materials: All the machines are made by stainless steel.

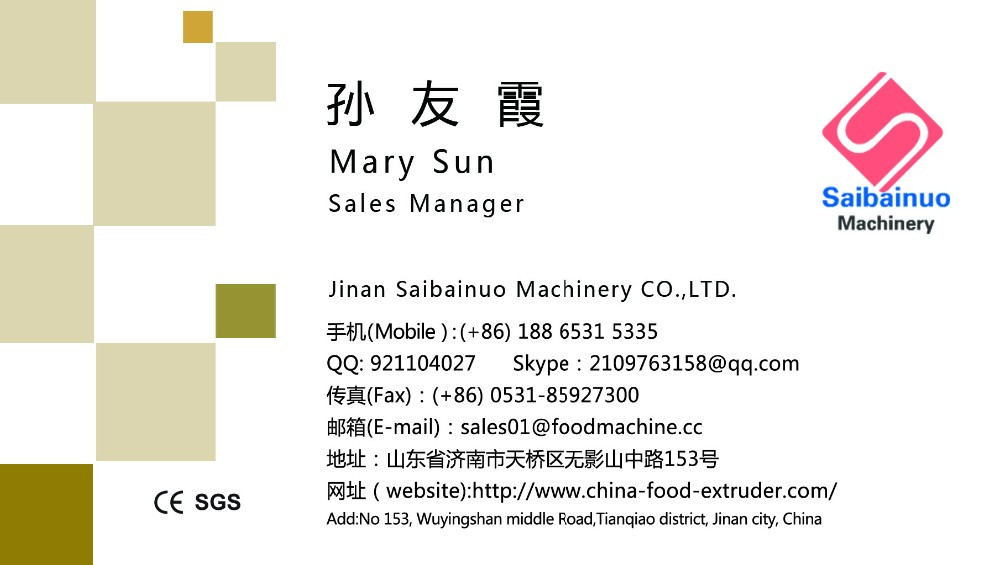

Jinan Saibainuo Machinery Co., Ltd for food machine manufacturering in China since 2004, we have professional engineer making nice quality machines in short time, also have special after sales service team work working 24H*7days to help you slove any kinds of problems, so with us your money in safe, your business safe.

This is our 250kg/h bugles production line in our factory.

the inside structure of our twin screw extruder.

The frying machine in our factory.

Detailed Images

Detailed Images

Name: twin screw extruder

Dimension(m): 2.6×1.0×1.3

Total power: 37kw

Main Motor Power:22KW

Cutting motor: 1.5kw

Heating power:10kw

Extruder diameter:Φ65 mm

Function:

Extrude and cook raw material into different size and shapes

Features:

Screw material is 38CrMoAl with nitriding treatment, the hardness is

60HRC.. The barrel also use good material, hardness is 55HRC.

The gear box has forced lubrication system.

All motors can be adjusted the speed by Inverter.

The Extruder can change different molds to produce different Shapes product.

Name: fryer

Dimension(m): 3.5×1.3×2.2

Total power: 45kw

Motor Power:1.5KW

Temperature: 20-300℃

Function:

Fry the Chips

Features:

The speed and the temperature can be adjusted.

There is oil filter to clean the oil.

Name: high speed mixer

Dimension(m): 1.1×0.8×1.4

Motor Power: 4KW

Speed: 400rpm

Throughput: 30kg per loading (5-6 minutes per loading)

Functions:

Mix powder raw material with water

Features:

1. stainless steel material(1.5mm).

2.High speed can mix material better than other slow mixer.

Name: flavoring line

Dimension(m): 2×0.8×1.8

Motor Power: 1.5KW

Function:

Scatter the seasoning powder on the food, The roller will mix the oil and seasoning powder evenly. Make food nice taste.

Feature:

Stainless steel material

Name: hositer

Dimension(m): 2.0×0.5×1.5

Motor Power:0.37KW

Function:

elevator conveys the food from the discharge-port of oven to the feed-charge port of oven

Features:

No leaking material and pollution

PVC conveyor belt

Can design different height to suitable for different machine.

Our Service

Our Service

Before sale services:

1.Provide the free consultation of the equipment.2.Provide the standard device and the flow chart.

3. According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

Services during the sales:

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Welcome to visit our factory or the domestic clients’ factory.

3.Inspect the machine before leaving the factory.

After sale services:

1.Oversea install and debug the equipment.

2.Train the first-line operator.

3.Provide the basic formula.Packing & Delivery

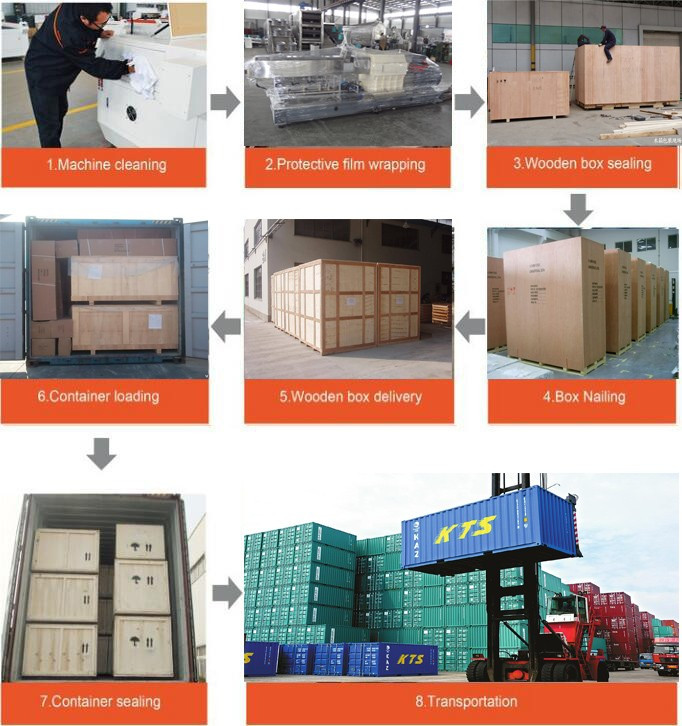

Packaging & Shipping:

1).packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film.Finaly pack them with wooden case.

2)Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code,house number,street,city,country); by ship-pls tell me your delivery port.

Related Products

Related Products

Cheetos making machine

98.6% Response Rate

Fish food making machine

97.8% Response Rate

Tsp making machine

99.5% Response Rate

Contact Us

- Microwave dryer dehydration sterilization machine

- AddressBawang Road, Licheng District, Jinan City, Shandong Province

- Phone(Working Time)86-531-4897119

Related News

| Microwave Technology in Traditional Chinese Medicine Production |

Product Categories

- laboratory drying equipment

- chinese herb dehydration and sterilization

- chinese medicine herb drying equipment

- chemical powder drying equipment

- Microwave dryer and sterilization machine

- chinese medicine extraction machine

- paper dehydrator and sterilizer

- paperboard drying equipment

- microwave fast food heating machine

- latex products drying machine

- microwave oven tunnel machine

- Microwave roasting equipment

- microwave sterilizer equipment

- Oil seeds Processing Line

- soybean oil machine

- Sesame Oil machine

- coconut oil processing machine

- mustard oil machinery

- Shea Nut Oil machine

- Castor Oil machine

- Walnut Oil machine

- Corn Germ Oil machine

- Rapeseed Oil machine

- Rice Bran Oil machine

- microwave dryer equipment

- cottonseed oil machine

- Sunflower Oil machine

- Peanut Groundnut Oil machine

- Small Scale Oil Refining Line

- palm fruit machine

- solvent extraction machine

- Full Continuous Refining Line

- Biodiesel Machine

- flaxseed oil Machine

- camellia oil Machine

- moringa seed oil machine

- Complete oil production line

- Seed Hydraulic Press Machine

- Large Scale oil Machine

- Edible Oil Filling Line

- oil Pretreatment Equipment

- Oil Extraction Equipment

- puffed snack food machinery

- corn filling snack machinery

- Fish food machine

- Animal food machinery

- Fried Kurkure machine

- Fried cheetos machine

- Baked kurkure machine

- Baked cheetos machine

- Corn flakes Machinery

- Frying snacks machinery

- Nacho Chips machinery

- Corn Chips machinery

- Tortilla machine

- doritos machine

- bugles machine

- Soyabean protein machine

- Extrusion food machine

- Macaroni pasta machinery

- Nutritious artifical rice food machine

- Bread crumbs machine

- Nutritional powder machine

- Modified starch machine

- modify starch machine

- Potato Chip Machine

- rice cracker machine

- Biscuit Production Line

- Textured Soya Protein machine

- Instant Noodles Production Line

- Fried Wheat Flour Snacks Making Machine

- Nutrition Bar Making Machine

- snack Food Packing Machines

corn tortilla doritos nacho chips processing line

corn tortilla doritos nacho chips processing line 2017 New Best Selling nacho chips processing line for sale

2017 New Best Selling nacho chips processing line for sale New arrive Crispy Nacho Tortilla Corn Chips Manufacturers

New arrive Crispy Nacho Tortilla Corn Chips Manufacturers hot selling Triangle Corn chips machine

hot selling Triangle Corn chips machine New arrive Crispy Corn Chips process line

New arrive Crispy Corn Chips process line