Home>Products>snack Food Packing Machines>Advanced Puffed food extruder processing line

Advanced Puffed food extruder processing line

- snack Food Packing Machines

snack Food Packing Machines

- China

- CE ISO

- One set Advanced Puffed food extruder processing line

- [email protected]

- 20*2*3m

- contact with us

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 195

Microwave dryer dehydration sterilization machineChina

-

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

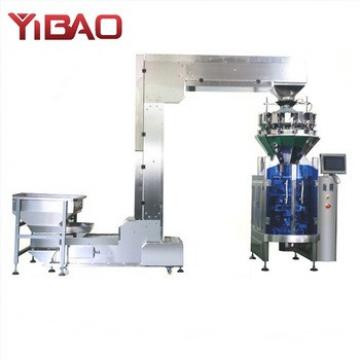

Advanced puff food extruder processing line 400kg/h

Advanced extrusion puff food machine /Puffed food extruder/Puff snack processing line/Puffed Advanced Puffed food extruder processing line production line 400kg/h

1.can produce many kinds extrusion food Advanced Puffed food extruder processing line

2.fully automatic,easy operation

3. use variety of grain as material

Extrusion Food machine Advanced Puffed food extruder processing line equipment adopts advanced extruding technique which can extrude two kinds of extrusion food with different textures and tastes out of double-screw extruder at the same time. It can produce a variety of Advanced Puffed food extruder processing line which are popular in the market, such as puffed snacks,extrusion food fragrant chicken, core-filling rolls, crispy stick,chips etc. By changing moulds and assistant equipments, it can also produce nutritional powder, grain gruel and many other leisure snacks in different snack shape. This automatic process line is of Advanced Puffed food extruder processing line level for its superior characters, such as, "applied to many materials, convenient operation and maintenance, low power consumption, high output".

Parameters:

Model | SLG65-C | SLG65-D | SLG70-A |

Installed power | 63.41kw | 54.13kw | 86.06kw |

Power consumption | 41kw | 35kw | 56kw |

Capacity | 100-130kg/h | 110-150kg/h | 250-300kg/h |

Dimension(mm) | 19500×1200×2000 | 23000×1800×2600 | 25000×2100×3000 |

Re.: The body plate and parts contacting food are all stainless steel.

All the brands of motors, inverters, and electrical elements can be adjusted as clients requirements.

Feature:

1 With adopting the latest Italy design concept to do proper improvement for the structure of screw and barrel to make sure that screw won’t grind inside the barrel. This will not only extend their use life, and also avoid the grind iron scrap mixing into the material.

2 Unique design of the diversion-cone enables the uniform discharging, and pressure equalizing for the discharge point of the die.

3 The rational barrel and screw cooling structure and effective heating unit assure the accuracy of temperature control.

Products:

Re.: Various shapes can be made by changing moulds.

Company Profile:

Since 1996, Advanced Puffed food extruder processing line Extrusion Machinery Co., Ltd is the professional manufacturer and the leader company of extrusion food machinery. Dayi Company congregates an expert team with twenty-year experiences in this extrusion machine industry. Our double-screw extruder and single-screw extruder can produce various puffed snacks, 2d/3d pellet, textured soya protein/fiber protein, corn flakes and breakfast cereals, popcorn, cheetos/kurkure, doritos/triangle chip, fried pasta, bread crumb, hamburger patty, dog/cat/fish feed, etc.

Our machines have largely occupied the Chinese market and cooperated with many well-known food companies. Meanwhile, have been exported for nearly twenty year to almost fifty countries. such as Malaysia (Mamee), Indonesia (Pt Mayora), Philippines (URC), Vietnam (Acecook), Thailand (R&B), Japan (Nissin), South Korea (Dowul), India (Shanti, Krashi), Pakistan, Russia, Kazakhstan, Uzbekistan, Turkmenistan, Jordan, Iran, Egypt, South Africa, Algeria, the Netherlands, Poland, Macedonia, Brazil, Argentina, Australia, etc.

We can not only provide you the best machines and services, but also the best food technology and the market useful information.

Re.: Whole company is in 7000 square meters, including Sales department, Finance department, Technical department, Supply department, Factory workshop, Warehouse, After-sale department, Worker cantin.

Clients:

Our machines have been exported to about 50 countries and regions.

Packing:

Re.: Fumigation-free pallet or full package can be chosen by clients.

All Service We Can Do for You:

--Pre-sales:

1. Free consultation about machine or process line and prompt reply;

2. Best quotation, information of machine or process line;

3. Test run machine in our factory;

4. Help arranging room and aboard for clients in our city;

--After-sales:

1. Arranging shipping matters of machines;

2. Overseas installation and debugging machines in clients’ factories;

3. Training clients’ workers for operating machines;

4. One year guaranty time of machines;

5. Technical support of machine and products for lifetime;

6. Supplying spare parts in best price for lifetime.

FAQ:

Generally questions you will meet during you choose the suitable machine:

1.if ours country's power supply is not 3ph 380v 50hz,different as you use in china,could you afford the suitable machine to us?

DAYI:Yes,we can afford the suitable machine accrodingly your power supply,for eg:3ph 415v 50hz,3ph 380v 60hz,3ph 440v 60hz,3ph 220v,60hz.

2.what is the material for the case of the machine?

DAYI:We use all stainless steel for the parts directly connect with the food.

3.what is the brand of Motor?eletronic components?

DAYI: We use ABB or Advanced Puffed food extruder processing line,it depends on your requirements.

4.If i can use one production line to produce many different sanck?

DAYI:one produciton line can produce only one category,but can produce different shape with change different molds.

5.what kind of fuel we can choose to start production?

DAYI:You can choose gas,diesel,eletricity as fuel,but pls tell your idea to our sales when you ask for quotaiton.

6.Could we visit your factory to check the machine carefully?

DAYI:Of course,we warmly welcome your coming to our factory to discuss of the detail.

7.How long is your machine's gurantee time?

DAYI:Normally our gurantee time is one year except for the easy broken parts.

8.Could you afford technician team to help ours installation and commissioning?

DAYI: We can send technician team to your country to help installation,we have professional teams with rich experience to do this job.

9:If we have very special requests for the production line,could you help me to work on it?

DAYI:Yes,we can afford customerized service, we have one technical team to Advanced Puffed food extruder processing line on this job,so they can afford the best service to you.

Thanks for your reading!

Contact Us

- Microwave dryer dehydration sterilization machine

- AddressBawang Road, Licheng District, Jinan City, Shandong Province

- Phone(Working Time)86-531-4897119

Related News

| Microwave Technology in Traditional Chinese Medicine Production |

Product Categories

- laboratory drying equipment

- chinese herb dehydration and sterilization

- chinese medicine herb drying equipment

- chemical powder drying equipment

- Microwave dryer and sterilization machine

- chinese medicine extraction machine

- paper dehydrator and sterilizer

- paperboard drying equipment

- microwave fast food heating machine

- latex products drying machine

- microwave oven tunnel machine

- Microwave roasting equipment

- microwave sterilizer equipment

- Oil seeds Processing Line

- soybean oil machine

- Sesame Oil machine

- coconut oil processing machine

- mustard oil machinery

- Shea Nut Oil machine

- Castor Oil machine

- Walnut Oil machine

- Corn Germ Oil machine

- Rapeseed Oil machine

- Rice Bran Oil machine

- microwave dryer equipment

- cottonseed oil machine

- Sunflower Oil machine

- Peanut Groundnut Oil machine

- Small Scale Oil Refining Line

- palm fruit machine

- solvent extraction machine

- Full Continuous Refining Line

- Biodiesel Machine

- flaxseed oil Machine

- camellia oil Machine

- moringa seed oil machine

- Complete oil production line

- Seed Hydraulic Press Machine

- Large Scale oil Machine

- Edible Oil Filling Line

- oil Pretreatment Equipment

- Oil Extraction Equipment

- puffed snack food machinery

- corn filling snack machinery

- Fish food machine

- Animal food machinery

- Fried Kurkure machine

- Fried cheetos machine

- Baked kurkure machine

- Baked cheetos machine

- Corn flakes Machinery

- Frying snacks machinery

- Nacho Chips machinery

- Corn Chips machinery

- Tortilla machine

- doritos machine

- bugles machine

- Soyabean protein machine

- Extrusion food machine

- Macaroni pasta machinery

- Nutritious artifical rice food machine

- Bread crumbs machine

- Nutritional powder machine

- Modified starch machine

- modify starch machine

- Potato Chip Machine

- rice cracker machine

- Biscuit Production Line

- Textured Soya Protein machine

- Instant Noodles Production Line

- Fried Wheat Flour Snacks Making Machine

- Nutrition Bar Making Machine

- snack Food Packing Machines

New Products

Neweek nitrogen case packing snack box fruit vacuum sealing machine

Neweek nitrogen case packing snack box fruit vacuum sealing machine Automatic crisps snacks french fries packaging machine

Automatic crisps snacks french fries packaging machine Widely Used Durable Full Automatic Snacks Packaging Machine

Widely Used Durable Full Automatic Snacks Packaging Machine Automatic food pouch packing filling machine, low cost potato chips snack sugar sachet packing machine

Automatic food pouch packing filling machine, low cost potato chips snack sugar sachet packing machine Semi-automatic stainless steel big bag filling machine for food industry packing

Semi-automatic stainless steel big bag filling machine for food industry packing