Home>Products>Fried Wheat Flour Snacks Making Machine>New design breakfast cereals corn flakes making extruder

New design breakfast cereals corn flakes making extruder

- Fried Wheat Flour Snacks Making Machine

Fried Wheat Flour Snacks Making Machine

- China

- CE ISO9001

- One set New design breakfast cereals corn flakes making extruder

- [email protected]

- 39000*1200*2200m

- contact with us

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 60

Microwave dryer dehydration sterilization machineChina

-

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

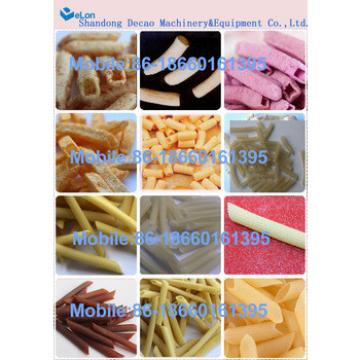

New design breakfast cereals corn flakes making extruder 1. Description for breakfast cereals extruderCorn flakes/breakfast cereals are a kind of breakfast with high nutritional value. They usually use corn powder and other cereals as main raw material, through mixing, extruding, flaking, drying, baking, coating and cooling, to get crispy flakes. It always service as breakfast cereal mixed with milk of coffee. But it can also be a kind of leisure snacks. This breakfast cereals corn flakes extruder process line can also make other shapes of cereals such as rings, balls, chocos, curls etc2. Raw materials: corn powder and other cereals

3. Products: corn powder and other cereals

4. Capacity: 120-150kg/h,200kg/h,300kg/h

5. Flow chart: Mixing ---Extrusion ----cooling---cutting- --drying

6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

7. breakfast cereals corn flakes making extruder Materials: All the machines are made by 304 stainless

8. Technical Parameters for breakfast cereals corn flakes extruder

| Model | Installed Power | Power Consumption | Capacity | Size |

| SLG65-III | 140kw | 90kw | 120-150kg/h | 39.0*1.2*2.2m |

| SLG70-III | 194kw | 147kw | 180-240kg/h | 41.0*1.5*2.2m |

| SLG85-III | 245kw | 185kw | 300-500kg/h | 43.0*3.5*4.3m |

Certifications

Certifications Detailed Images

Detailed Images

Mixer Function and Features:

Name: Mixer

Brand: Datong

Original: China

It is used to mix raw materials.We can supply different capacities to meet your demands: 30kg/batch,50kg/batch,100kg/batch and so on.

breakfast cereals extruder main part:

Name: screw conveyor

Brand: Datong

Original: China

It is used to convey the mixed raw materials to the feeder of the extruder.There is no leaking,dusting and pollution during the conveying.

Cutting System:

1.The blades is made of alloy steel,Very sharp.

2.It can cut the product easily.

3.Hardness material an used long time.

4.it can fix more cutter according require.

Double screw food extruder Features:

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

breakfast cereals extruder main part:

Name: Cooling Conveyor

Brand: Datong

Original: China

It is full set stainless steel.The height of the hoister can be adjusted based on the requirement.

Machine Parts: dryer

1. This dryer has the compact structure, small occupying, large drying area, small surface area, slight radiating heat and high thermal efficiency.2.The belt and the heat preservation use the stainless steel; it is suitable for food safe industry level.

3.The running speed of belt net can be controlled (frequency controlling system)

4.The temperature can be controlled willfully and designed according to the need.Our Service

1.Pre-shippment Inspection

a.) Supplier should trial run whole line at supplier's factory before shipment;

b.) Supplier has to run the machine at least 1hour for each machine;

c.) All raw materials for that trial run to be arranged by supplier at their cost.

2.Installation & Training

a.) The seller will send one engineer to install the machinery.

b.) Buyer is responsible for finding a translator locally for easy understanding.

c.) The customer will be asked to provide room, board, round-trip transportation, and a nominal $60 daily subsidy per person for their working days.

d.) Period of installation:The buyer should arrange at least 4 workers including one electric technician to help our engineer for installation. The raw material, workshop electric source should be well prepared before installation. On base of the above request, the installation period is7-14 days including training the operater. A possible delay of the installation period will be additionally invoiced.

e.) The total length of the installation time depends on number and qualification of the available local stuff. A possible delay of the installation period will be additionally invoiced.

f.) We will provide on-site service after 1 year. The customer will be asked to provide room, board, round-trip transportation, and a nominal $50 daily subsidy per person.

g.) The seller is responsible for the fare of the visa in China.

3.Service&Guarantee

a.) Free consultation service before, during, and after sales;

b.) Free project planning and design services;

c.) Free debugging of equipment until everything is functional;

d.) Free management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Free training of equipment maintenance and operating personally;

All Machine will be cleaned and whole wraped by plastic film to avoid any scratch;

Extra Spare Parts,wires and tool box will be placed with the package;

Delivery Department and sales will check the list to avoid any missing;

All Wooden Cases for protecting the machine during long-time shipment.

Our Company

Our Company

Jinan Datong Extrusion Machinery Co., Ltd is a professional food machinery manufacturer in Jinan city shandong province China.With our many years research and development extrusion technics has been widely used in more fields.

Our products consist of extrusion snack machine, twin screw food extruder, breakfast cereal and corn flakes machine, pet food machines and floating fish feed machinery,textured soya protein machine,modified starch machine, artificial rice making machine,bread crumb machine,single screw extruder,potato chips machine and biscuits machine, instant flour machine,flat bread machine,ect. We can also provide special design and product according to our clients` special requirements.

Now we have exported our machines to many countries, such as Malaysia, Indonesia. Pakistan, Sri Lanka, Brazil etc., and get good reputation from the clients. Some of them become our agents.

Welcome to visit Datong Extrusion Company!

Related Products

FAQ

FAQNew design breakfast cereals corn flakes making extruder

1. Are You a manufacturer or a trading company?

We are professional manufacturer of food making machine

2. Where is your factory located?

Our factory is located in Jinan city,Daqiao Haojing industrial park,Tianqiao Zoon,Shangdong Province,China

3. What's your price of your food making machine?

Please contact us by send inquiry to us directly ,We will reply you as soon as possiable

4. How to support me,if I don't know how to use it?

Free training within the warranty period will be provided by telephone or email or skype.We also can let our technican to customer's company to provided training and support

5. If machines' wearing parts need changing ,what should we do?

We can offer wearing parts all the time ,and offer video to show how to change it.

6. What's the payment term,if we want to buy machines ?

L/C,100%T/T,New design breakfast cereals corn flakes making extruder Trade Assurance,T/T30% down payment ,70ºlance delivery.

Zhang Lee

Director of sales department

Whatsapp/New design breakfast cereals corn flakes making extruder +0086 18396813015

Tel: 0086 531 88085286

Contact Us

- Microwave dryer dehydration sterilization machine

- AddressBawang Road, Licheng District, Jinan City, Shandong Province

- Phone(Working Time)86-531-4897119

Related News

| Microwave Technology in Traditional Chinese Medicine Production |

Product Categories

- laboratory drying equipment

- chinese herb dehydration and sterilization

- chinese medicine herb drying equipment

- chemical powder drying equipment

- Microwave dryer and sterilization machine

- chinese medicine extraction machine

- paper dehydrator and sterilizer

- paperboard drying equipment

- microwave fast food heating machine

- latex products drying machine

- microwave oven tunnel machine

- Microwave roasting equipment

- microwave sterilizer equipment

- Oil seeds Processing Line

- soybean oil machine

- Sesame Oil machine

- coconut oil processing machine

- mustard oil machinery

- Shea Nut Oil machine

- Castor Oil machine

- Walnut Oil machine

- Corn Germ Oil machine

- Rapeseed Oil machine

- Rice Bran Oil machine

- microwave dryer equipment

- cottonseed oil machine

- Sunflower Oil machine

- Peanut Groundnut Oil machine

- Small Scale Oil Refining Line

- palm fruit machine

- solvent extraction machine

- Full Continuous Refining Line

- Biodiesel Machine

- flaxseed oil Machine

- camellia oil Machine

- moringa seed oil machine

- Complete oil production line

- Seed Hydraulic Press Machine

- Large Scale oil Machine

- Edible Oil Filling Line

- oil Pretreatment Equipment

- Oil Extraction Equipment

- puffed snack food machinery

- corn filling snack machinery

- Fish food machine

- Animal food machinery

- Fried Kurkure machine

- Fried cheetos machine

- Baked kurkure machine

- Baked cheetos machine

- Corn flakes Machinery

- Frying snacks machinery

- Nacho Chips machinery

- Corn Chips machinery

- Tortilla machine

- doritos machine

- bugles machine

- Soyabean protein machine

- Extrusion food machine

- Macaroni pasta machinery

- Nutritious artifical rice food machine

- Bread crumbs machine

- Nutritional powder machine

- Modified starch machine

- modify starch machine

- Potato Chip Machine

- rice cracker machine

- Biscuit Production Line

- Textured Soya Protein machine

- Instant Noodles Production Line

- Fried Wheat Flour Snacks Making Machine

- Nutrition Bar Making Machine

- snack Food Packing Machines

fried snack food making mahine

fried snack food making mahine ss304 stainless steel extrusion snacks process line food processing industries

ss304 stainless steel extrusion snacks process line food processing industries fried wheat flour chips processing line

fried wheat flour chips processing line puff corn snacks making line

puff corn snacks making line extruder bugle snack processing line

extruder bugle snack processing line