Home>Products>Baked cheetos machine>Corn Kurkure Snack Food Making Machine

Corn Kurkure Snack Food Making Machine

- Baked cheetos machine

Baked cheetos machine

- China

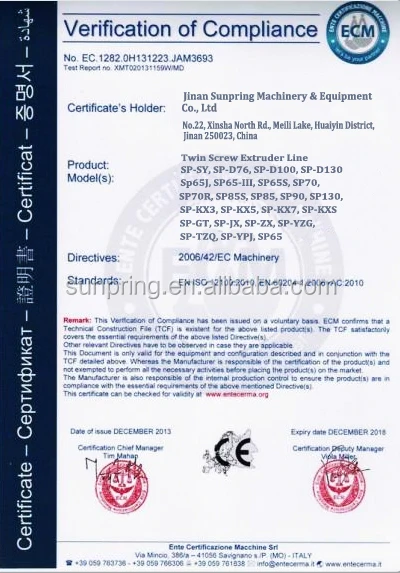

- CE

- One set Corn Kurkure Snack Food Making Machine

- [email protected]

- 20000*1200*2500mm

- contact with us

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 131

Microwave dryer dehydration sterilization machineChina

-

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Corn Kurkure Corn Kurkure Snack Food Making Machine Making Machine

A. Corn Kurkure Snacks Picture

B. Description For Corn Kurkure Machine

Corn kurkure are produced by blending corn grits and water. The mixture is heated under pressure, and then extruded through a die. The texture of the snack is formed as a result of contact withhot air, causing steam in the mixture to expand and creating its characteristic texture.

Normally, it was named kurkrue in India, Cheetos in America, and South African called it nik naks.

1. Raw materials

Adopts corn grits as raw materials meanwhile mixing with water and oil

2. Products those machines can be to produce cheetos, kurkure, nik naks, cheese curls and corn curls

3. Capacity100--150kg/h

4. Flow Chart Mixing system---Extrusion system----Frying system ---Flavoring system---Packing system

5. Voltage in China

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

C. Kurkure Machines Flow Chart

D. Mainly Machines

Vertical Mixer

Rotary Head Extruder Machine

Continuous Fryer

E. After-Sales Service

Turnkey project is available for us, our engineer will install and commissioning in your factory.

Pre-sale services

1). Provide the free consultation of the equipment

2). Provide the standard device and the flow chart

3). According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

4). Welcome to visit our factory or the domestic clients’ factory.

Services during the sales

1). Provide factory layout according to your factory size in advance.

2). Provide the basic formula

3). Inspect the machine before leaving the factory.

4). Oversea installation and commissioning the equipment.

5). Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to maintain machines during daily working.

6). Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide technology support with you forever.

After sale services

1). Provide the spare parts will at preferential price for an extended long time.

2). Provide technical exchanging

F. Engineers Installed Machines in customers' factory

At present, Our Company locks in 70% market share in China, and our products have been selling well to more than 90 countries, such as Germany, Australia, Ukraine, Malaysia, Indonesia, Syria, Philippine, Thailand,Romania, South America, Middle East, Africa and other countries or regions.

Customer visited us

G. Packing & Factory

Wooden case and stretch film package

Workshop Machines

Jinan Sunping Machinery & Equipment Co., Ltd. is a professional food machinery manufacturer in China, we are able to supply niche markets for different countries clients, so more and more customers choose to trust us and the annual turnover increasing year by year.

If you are a newer for this industry, hope we can assist you to construct your factory in local and to understand the machines.

If you are a experienced in food industry, we hope to establish mutually beneficial trading relations between us and expand your business.

H. Company News

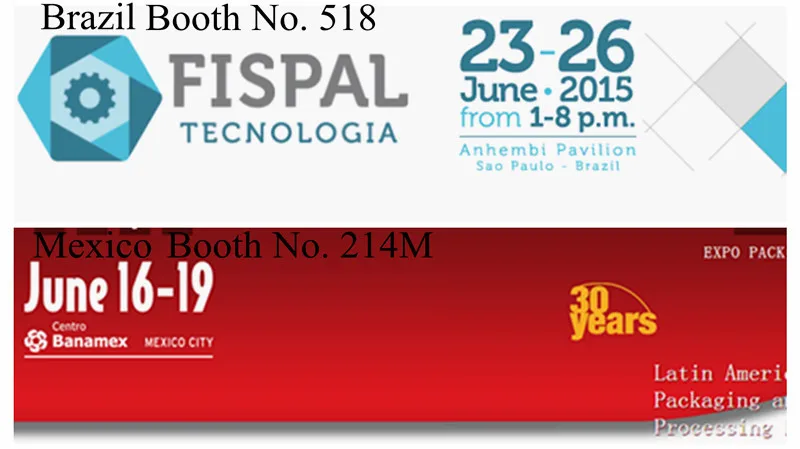

We will attend the EXPO PACK from 16-- 19th June 2015 in Mexico City. Our Booth No. is 5818. And we will attend the Fispal Tecnologia from 23th-26th June 2015 in Sao Paulo, Brazil, the booth number is 214M, welcome to visit our booth.

I. RAQ

1). Space required for kurkure production line

Normally, according to our experience, a space with 20×3×3M is enough for our whole production line. But consideration of raw material and final production warehouse, dressing room, pre-mix preparation room etc. You can design it according to your requirement.

2). Operator Needed: 3-5 Normally, one manager, two operator and one technician

3). Power Consumption: 40kw

4). Guarantee time: one year

5). We provide Turnkey Project

a. Provide factory layout according to your factory size in advance.

b. Provide the recipe when your esteemed company cooperate with us.

c. Before place the order, we invite you to visit us and make demonstration for you in workshop

d. Before delivery the machines, we invite you to inspect all the machines.

e. Installation and commissioning in your factory for 15days

6). Payment terms: 30% T/T as down payment, 70% by irrevocable L/C at sight or T/T before delivering

7). Delivery time: 30 days after receipt the deposit

To Learn More Details, Welcome To Contact Us.

Contact Us

- Microwave dryer dehydration sterilization machine

- AddressBawang Road, Licheng District, Jinan City, Shandong Province

- Phone(Working Time)86-531-4897119

Related News

| Microwave Technology in Traditional Chinese Medicine Production |

Product Categories

- laboratory drying equipment

- chinese herb dehydration and sterilization

- chinese medicine herb drying equipment

- chemical powder drying equipment

- Microwave dryer and sterilization machine

- chinese medicine extraction machine

- paper dehydrator and sterilizer

- paperboard drying equipment

- microwave fast food heating machine

- latex products drying machine

- microwave oven tunnel machine

- Microwave roasting equipment

- microwave sterilizer equipment

- Oil seeds Processing Line

- soybean oil machine

- Sesame Oil machine

- coconut oil processing machine

- mustard oil machinery

- Shea Nut Oil machine

- Castor Oil machine

- Walnut Oil machine

- Corn Germ Oil machine

- Rapeseed Oil machine

- Rice Bran Oil machine

- microwave dryer equipment

- cottonseed oil machine

- Sunflower Oil machine

- Peanut Groundnut Oil machine

- Small Scale Oil Refining Line

- palm fruit machine

- solvent extraction machine

- Full Continuous Refining Line

- Biodiesel Machine

- flaxseed oil Machine

- camellia oil Machine

- moringa seed oil machine

- Complete oil production line

- Seed Hydraulic Press Machine

- Large Scale oil Machine

- Edible Oil Filling Line

- oil Pretreatment Equipment

- Oil Extraction Equipment

- puffed snack food machinery

- corn filling snack machinery

- Fish food machine

- Animal food machinery

- Fried Kurkure machine

- Fried cheetos machine

- Baked kurkure machine

- Baked cheetos machine

- Corn flakes Machinery

- Frying snacks machinery

- Nacho Chips machinery

- Corn Chips machinery

- Tortilla machine

- doritos machine

- bugles machine

- Soyabean protein machine

- Extrusion food machine

- Macaroni pasta machinery

- Nutritious artifical rice food machine

- Bread crumbs machine

- Nutritional powder machine

- Modified starch machine

- modify starch machine

- Potato Chip Machine

- rice cracker machine

- Biscuit Production Line

- Textured Soya Protein machine

- Instant Noodles Production Line

- Fried Wheat Flour Snacks Making Machine

- Nutrition Bar Making Machine

- snack Food Packing Machines

Cheese Curls Snacks Food Machine

Cheese Curls Snacks Food Machine Kurkure Food Extrusion Machine

Kurkure Food Extrusion Machine Maize/corn flavor low cost high output kurkure snacks food production line

Maize/corn flavor low cost high output kurkure snacks food production line Fried baked kurkure nik naks corn curls snack cheetos extruder

Fried baked kurkure nik naks corn curls snack cheetos extruder Fried or Baked Cheetos Twisted Puffs Cheese Flavored Snacks Making Machine Manufacturer

Fried or Baked Cheetos Twisted Puffs Cheese Flavored Snacks Making Machine Manufacturer