Home>Products>snack Food Packing Machines>Hot sales automatic candy and snack food packing machine

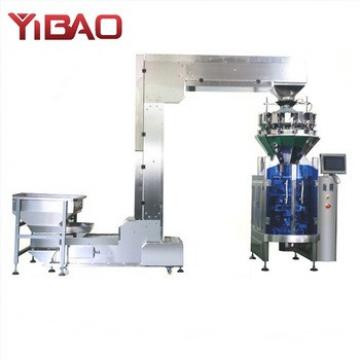

Hot sales automatic candy and snack food packing machine

- snack Food Packing Machines

snack Food Packing Machines

- China

- CE Certification

- One set Hot sales automatic candy and snack food packing machine

- [email protected]

- 1400*1100*1560(mm)

- contact with us

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 138

Microwave dryer dehydration sterilization machineChina

-

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Microwave dryer dehydration sterilization machine2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

WP-M series automatic vertical packaging machine absorb foreign advanced technology and high quality.High-performance automatic packaging machine, with complete automatic feeding, metering, bag making, filling, sealing, date printing and product output and a series of automatic functions. The machine uses high-precision servo film transporting system, PLC program control, advanced touch interface, photoelectric automatic location tracking, digital temperature control, so that the whole operation is more simple and perfect. In the food packaging industry, it improve production efficiency, reduce labor intensity. In a word, our machine is the best choice for the high class package.

Feature

◎PLC control, man-machine interface, easy to operate and maintaince.◎Driven by servo motor and optical tracking devices to keep accuracy and high accuracy.

◎The frame of machine is made of 304 stainless steel, equiped with auto-stop protection function when open the door.

Product Application

◎Applicable bag type:Pillow bag,Gusset bag,Seal type bag.

◎Applicable film materials:Avariety of laminated films,single-layer PE film,film thickness range 0.03mm~0.15mm.

◎Applicable packing materials:A variety of recreation food,deep frozen food,milk powder,coffee,oatmeal,granulated sugar,salt,puffed food,rice,herbal,tea,small hardware etc.

Machine Parts

Change the bag forming tube As figure 4-10.1 shows.

Step of change:

①Open the vertical sealing handle and open outwards the vertical sealing morethan 90 degrees.②Steer the press handle up and fixed board of bag forming tube will lift.③Hold the struts in hands and remove the bag forming tube.④Hold the two side of the struts of new bag forming tube,and put it on thesupporting board and then the fixed pole of the fixed board will face the press boardof the bag forming tube,then stir the press handle down, then press board will fasten the fixed board.

Machine Parts

●Human-machine interface: As is shown in the figure 5-1.1, human-machineinterface (touch screen) is the operational system of the whole packing machine.It is

located on the top of electric box so that it is easy for touching.

Machine Parts

Running Button : As is shown in the figure 5-1.2,running button controls functions of the machine. There are red (stop),yellow(make one bag) and blue(fill

and run)buttons.They are under the touch screen.

Replace the film

Our packaging machine film releasing axis is air axis. There are claw in the axis,claw is pushed under the pressure when it is charging and blow film roller tube,then the film is fixed on the film releasing axis. When it is exhausting, the claw will be pulled back, the film can be easily removed from the film releasing axis, as the figure 4-9.1 shows.

Machine Parts

Vertical sealing roller adjustment(joint sealing): joint sealing is individualsealing rollers, driven by cylinders back and forward, as the figure 4-7.5 shows

Machine Parts

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Machine Parts

Overview: sealing clamp material stop is one of automatically recognition functions of packaging machine, which is used to detect horizontal sealing whether clamp material; opening limited is protection function, when the parameter setting of “H Seal Original” is too high, opening limited electric eye can avoid theabnormal opening (when abnormal opening, the spare parts will collide and the machine will be damaged), and control in normal range, as Figure 4-7.1 shows..

Machine Parts

No film detection: As is shown in the figure 4-2.6,“electric-eye tracker 1” and“electric-eye tracker 6” are no film detection electric-eye trackers. Whenpackaging film runs out, the roller will drop to the lowest place or be pulled to

12 the top. When the roller in the lowest place,it can detected by “electric-eye tracker 1”. In the top, it can detected by the “electric-eye tracker 6”.

Machine Parts

Servo motor parameters are set as the factory settings, do not change it. Under normal circumstances, only motor positive inversion and command pulse often need to adjust parameters.

Bag types

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Related Products

WP-H Series ( high speed )

WP-H Series ( high speed )WP-M Series

( middle speed )WP-E Series

(economic type)

LIner Weigher

Auger Filler

Multihead Weigher

Certificates

About us

About us

Foshan Wilpac Packaging Machinery Co Ltd, located in Foshan. We specialized in R&D, manufacturing, marketing, and offering aftersales services for high level packaging machinery and we are dedicated to become a High Tech Enterprise in packaging machinery industry.

We have modern standard factory, visionary venture team, skillfull R&D team and strong aftersales technical backup. We Hot sales automatic candy and Hot sales automatic candy and snack food packing machine packing machine on the R&D of the food packaging machinery, we absorbed and advanced packaging machinery technology from overseas and made improvements and innovations. We aim at becoming benchmarking and flag bearer in dometic packaging machinery industry.

So far, our packaging machinery is sold to Europe, America, Middle East and Southeast Asia etc. And its performance and quality is widely accepeted and praised by our customers.

We take "innovative technology, Optimal Management, Service Integrity, Market Development" as our philosophy. We adhere to the company tenet of "technology first, the market as guide, quality is fundamental, reputation is guarantee". We aim at providing the most automated food packaging machinery and equipment to the clients from all over the world.

Q1: Are you the factory or trading company ?

A1: We are factory, packaging machinery manufacturer, selling all around the world and models are hot sales in America, Germany, Austria and so on, getting high appreciated from our customers.

Q2: What kinds of bags can be packed ?

A2: We have many kinds of bags, such as pillow bag, back sealing gusset bag, side sealing gusset bag, four seal bag, "M" bag, triangle bag and so on.

Q3: How about the MOQ of completed packaging machine ?

A3: 1 sets.

Q4: May i purchase the packaging machinery spare parts too ?

A4: Sure, highly appreciated.

Q5: What is the delivery date ?

A5: If materials are in stock, delivery date is about 20-25days. If not, delivery date is about 40-50days.

Q6: Why would choose Wilpac ?

A6: We have strong R&D team and aftersales services, any questions just feel free to contact with us.

If you are interested in our products

Please feel free to contact me

Welcome to Wilpac !

Contact Us

- Microwave dryer dehydration sterilization machine

- AddressBawang Road, Licheng District, Jinan City, Shandong Province

- Phone(Working Time)86-531-4897119

Related News

| Microwave Technology in Traditional Chinese Medicine Production |

Product Categories

- laboratory drying equipment

- chinese herb dehydration and sterilization

- chinese medicine herb drying equipment

- chemical powder drying equipment

- Microwave dryer and sterilization machine

- chinese medicine extraction machine

- paper dehydrator and sterilizer

- paperboard drying equipment

- microwave fast food heating machine

- latex products drying machine

- microwave oven tunnel machine

- Microwave roasting equipment

- microwave sterilizer equipment

- Oil seeds Processing Line

- soybean oil machine

- Sesame Oil machine

- coconut oil processing machine

- mustard oil machinery

- Shea Nut Oil machine

- Castor Oil machine

- Walnut Oil machine

- Corn Germ Oil machine

- Rapeseed Oil machine

- Rice Bran Oil machine

- microwave dryer equipment

- cottonseed oil machine

- Sunflower Oil machine

- Peanut Groundnut Oil machine

- Small Scale Oil Refining Line

- palm fruit machine

- solvent extraction machine

- Full Continuous Refining Line

- Biodiesel Machine

- flaxseed oil Machine

- camellia oil Machine

- moringa seed oil machine

- Complete oil production line

- Seed Hydraulic Press Machine

- Large Scale oil Machine

- Edible Oil Filling Line

- oil Pretreatment Equipment

- Oil Extraction Equipment

- puffed snack food machinery

- corn filling snack machinery

- Fish food machine

- Animal food machinery

- Fried Kurkure machine

- Fried cheetos machine

- Baked kurkure machine

- Baked cheetos machine

- Corn flakes Machinery

- Frying snacks machinery

- Nacho Chips machinery

- Corn Chips machinery

- Tortilla machine

- doritos machine

- bugles machine

- Soyabean protein machine

- Extrusion food machine

- Macaroni pasta machinery

- Nutritious artifical rice food machine

- Bread crumbs machine

- Nutritional powder machine

- Modified starch machine

- modify starch machine

- Potato Chip Machine

- rice cracker machine

- Biscuit Production Line

- Textured Soya Protein machine

- Instant Noodles Production Line

- Fried Wheat Flour Snacks Making Machine

- Nutrition Bar Making Machine

- snack Food Packing Machines

New Products

Neweek nitrogen case packing snack box fruit vacuum sealing machine

Neweek nitrogen case packing snack box fruit vacuum sealing machine Automatic crisps snacks french fries packaging machine

Automatic crisps snacks french fries packaging machine Widely Used Durable Full Automatic Snacks Packaging Machine

Widely Used Durable Full Automatic Snacks Packaging Machine Automatic food pouch packing filling machine, low cost potato chips snack sugar sachet packing machine

Automatic food pouch packing filling machine, low cost potato chips snack sugar sachet packing machine Semi-automatic stainless steel big bag filling machine for food industry packing

Semi-automatic stainless steel big bag filling machine for food industry packing